Many tool cases have hard outer shells that protect the tools inside from water, dirt, drops and other sources of damage. The interiors may be lined with soft foam or they could have hard plastic inserts that hold the tools in place. Read More…

One of the top carrying case suppliers, Princeton Case West provides quality carrying cases, custom cases, shipping cases, plastic cases, aluminum cases, tool cases, computer cases, instrument cases, transit cases and ATA cases. Princeton Case West offers custom foam inserts for varying applications. From design to delivery, Princeton Case West offers the complete package at affordable pricing.

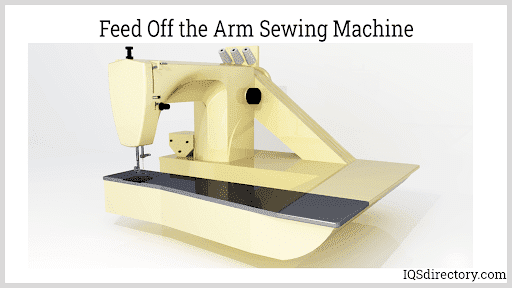

Our cases come in various configurations such as soft sewn cases, hard cases, model cases, exhibit cases, and more. We are experts in contract sewing and there is no project too complex for our experts. With manufacturing experience dating back to 1994 we are confident we can provide you with a top of the line custom carrying case.

Since 1971, Melmat, Inc. has been a dedicated leader in providing high-quality carrying cases that meet the diverse needs of our customers across various industries. As a trusted source for stock and custom case solutions, we cater to a wide range of industries and applications, understanding that every case must meet specific durability, protection, and functionality standards.

At CSE Packaging, we stand as a trusted leader in the realm of carrying cases, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

Wilson Case proves that shipping cases don’t have to be heavy to be tough! As a leading manufacturer with over 30 years of designing, our transit cases protect everything from antennas to computers, delicate mirrors & plasmas, scientific instruments, an $800 million space telescope, military, athletic & event equipment. When our standard cases don’t meet your needs, try our custom case...

At ATS Cases, Inc., we take pride in designing and manufacturing high-quality carrying cases that protect valuable equipment in even the most demanding environments. We work closely with our customers to create solutions that balance durability, functionality, and style, ensuring every case we produce meets the exact requirements of its intended application.

More Tool Case Manufacturers

Comprehensive Guide to Tool Cases: Materials, Functions, and Industry Applications

In today’s demanding business, industrial, and engineering environments, tool cases play a critical role in safeguarding valuable equipment. Whether you’re an electrician, telecom technician, military professional, engineer, or even a homeowner, the right tool case ensures your tools remain protected, organized, and ready for action. This in-depth guide explores the essential functions, material options, manufacturing processes, and the most important factors to consider when selecting the ideal tool case for your specific needs.

Why Are Tool Cases Essential?

Tool cases are designed to provide robust protection from shock, vibration, and harsh environmental conditions such as moisture, salt spray, dust, and even water immersion. These protective carrying cases are critical for ensuring the longevity and reliability of tools and sensitive equipment, especially in rugged or unpredictable settings. With increasing demands for mobility and durability, modern tool cases integrate advanced materials and innovative designs to address a wide range of use cases—from field service and industrial maintenance to photography, emergency response, and home repair.

Key Functions and Benefits of Tool Cases

- Shock and Vibration Protection: High-performance tool cases are engineered to absorb impacts, reducing the risk of equipment damage during transport or handling. This is essential for protecting sensitive instruments, power tools, and electronic devices.

- Environmental Sealing: Seals, gaskets, and closures such as zippers or latches safeguard contents from dust, water, moisture, salt spray, and corrosive elements.

- Organizational Features: Customizable compartments, shelves, foam inserts, and pockets enable efficient organization of tools and accessories, facilitating quick access and minimizing downtime.

- Portability and Ergonomics: Features like wheels, telescoping handles, and lightweight materials make transportation easier, even across demanding terrains or job sites. Consider: Which tool case designs offer the best portability?

- Security: Lockable latches, tamper-resistant hardware, and reinforced corners help protect valuable or sensitive equipment from theft or unauthorized access.

- Customization: Many tool cases can be tailored with branding, foam cutouts, color options, and specialized hardware to fit unique tool sets or corporate requirements. Ask yourself: How can I design a custom tool case for my industry?

Popular Materials Used in Tool Case Manufacturing

Modern tool cases are fabricated from a variety of materials, each offering distinct advantages in terms of strength, weight, durability, and cost. Selecting the right material is crucial for matching your case to its intended environment and use case. Below is an overview of the most common materials and their applications:

- Aluminum Tool Cases: Renowned for their lightweight yet durable construction, aluminum tool cases provide excellent impact resistance and corrosion protection. They are ideal for professionals seeking a blend of security, portability, and a sleek appearance. Aluminum is widely used in aerospace, defense, medical, and high-end photography applications.

- High-Density Polyethylene (HDPE): This thermoplastic is known for its strength-to-weight ratio, chemical resistance, and durability under tough conditions. HDPE tool cases are common in industrial, utility, and field service sectors where ruggedness and low maintenance are priorities.

- Fiberglass Reinforced Polyester (FRP): FRP composites offer high rigidity, impact resistance, and excellent weatherproofing properties. They are frequently used for heavy-duty field equipment, telecom infrastructure, and laboratory instruments. Curious about composite case advantages? What are the pros and cons of composite tool cases?

- Carbon Fiber: Favored for its ultra-lightweight and superior strength, carbon fiber is used in specialized tool cases for aviation, sports, and high-performance industries. Its premium cost is justified by the unmatched strength-to-weight ratio and advanced aesthetics.

- Rotationally Molded Polyethylene (Roto-Molded): Roto-molded cases offer exceptional impact resistance and uniform wall thickness, making them ideal for military, law enforcement, and outdoor adventure applications where the highest durability is required.

- Linear Low-Density Polyethylene (LLDPE): LLDPE provides flexibility and toughness, often used for custom-molded cases where both impact absorption and cost efficiency are important.

Material Comparison Table

| Material | Strength | Weight | Weather Resistance | Best For |

|---|---|---|---|---|

| Aluminum | High | Light | Excellent | Aerospace, Defense, Medical, Photography |

| HDPE | High | Moderate | Good | Industrial, Field Service |

| FRP | Very High | Moderate | Excellent | Heavy-Duty, Telecom, Lab Instruments |

| Carbon Fiber | Ultra High | Ultra Light | Excellent | Aviation, Sports, High-Performance |

| Roto-Molded Polyethylene | Very High | Heavy | Excellent | Military, Outdoor, Law Enforcement |

| LLDPE | Moderate | Light | Good | Custom Cases, General Use |

Manufacturing Methods: How Are Tool Cases Made?

The fabrication methods used to manufacture tool cases directly impact performance, durability, and cost. Understanding these processes helps buyers evaluate which tool case best matches their application and budget. Here are the most common methods:

- Composite Molding: Used for fiberglass reinforced polyester (FRP) and carbon fiber cases, this process involves weaving, knitting, braiding, or stitching fibers together before bonding them with a tough plastic matrix. The composite is then molded under heat or compression, resulting in a stiff and resilient shell.

- Wet Molding: Similar to composite molding, but involves reinforcing the matrix with fibers during the molding phase, creating a high-strength form that can be customized for specific tool layouts.

- Rotational Molding (Roto-Molding): A process where polyethylene powder is rotated and heated inside a mold, forming a seamless, thick-walled case. Roto-molded cases are prized for their extreme durability and ability to withstand rough handling and environmental abuse.

- Extruded Aluminum Framing: For cases with aluminum or hybrid construction, extruded aluminum bars or rods are forced through a die to achieve the desired cross-section, then welded and assembled to create a robust frame. This method provides superior structural integrity and lightweight portability.

- Injection Molding: Commonly used for HDPE, LLDPE, and other plastics, injection molding forces molten plastic into a mold cavity, allowing for high-precision, repeatable case manufacturing at scale.

Internal Frames and Shock Mounting Systems

Many tool cases—especially those intended for large, heavy, or delicate equipment—feature internal frames constructed from extruded aluminum. These frames are welded and mounted within the case to provide structural support and to securely hold tools in place. For added protection, shock mounts are often included. These mounts absorb vibrations and transfer potentially damaging energy away from the tools, reducing the risk of breakage or malfunction during transit.

Types of Tool Cases: Matching Case Design to the Application

With such a diverse range of applications and user requirements, tool cases are available in a variety of configurations. Choosing the right type of tool case ensures optimal protection, organization, and ease of use. Here are some popular options:

- Hard Shell Tool Cases: Offer maximum impact protection and are favored for transporting sensitive electronics, measuring instruments, or specialized equipment.

- Soft Tool Cases and Tool Bags: Made from heavy-duty fabrics, these are lighter and more flexible, ideal for tradespeople who need quick access and portability for hand tools.

- Rolling Tool Cases: Equipped with wheels and extendable handles, these cases are perfect for professionals moving heavy or bulky tool sets between work sites.

- Waterproof and Dustproof Tool Cases: Designed with airtight seals, these cases are essential in marine, field, and outdoor applications where moisture or particulate ingress could damage equipment.

- Custom Foam-Inserted Tool Cases: Offer precise tool organization and protection, frequently used for high-value or fragile instruments in medical, aviation, and laboratory sectors.

- Modular Tool Cases: Allow users to reconfigure compartments and dividers as needs evolve, offering versatility for growing tool collections or changing job requirements.

Industry Applications for Tool Cases

The versatility of modern tool cases makes them indispensable across a wide spectrum of industries and use cases. Here are a few examples:

- Engineering and Field Service: Technicians rely on rugged tool cases to transport calibration devices, diagnostic instruments, and repair tools to remote or challenging environments.

- Military and Defense: Secure, shockproof, and weatherproof cases are used to carry communications equipment, weapons, and sensitive electronics.

- Telecommunications: Installers and maintenance crews use specialized tool cases with custom foam inserts and compartments to organize cables, meters, and connectors.

- Medical and Laboratory: Healthcare professionals utilize sterile, impact-resistant cases for surgical instruments, medical devices, and specimen transport.

- Photography and Videography: Photographers protect valuable cameras, lenses, and lighting gear with padded, waterproof cases during travel and outdoor shoots.

- Industrial Maintenance: Heavy-duty tool cases are standard for plant maintenance, construction, and utility operations where durability and organization are essential.

- Homeowners and Hobbyists: DIY enthusiasts and home repair specialists use portable tool cases for organizing hand tools, power tools, and accessories.

How to Choose the Right Tool Case: Decision Factors and Buyer Considerations

Selecting the ideal tool case requires a careful assessment of your specific needs, work environment, and budget. Here are the most important decision factors to consider:

- Level of Protection Needed: Do you require impact resistance, waterproofing, dust sealing, or all of the above? Assess your job site hazards and match your case features accordingly.

- Portability Requirements: Will you be carrying your tool case by hand, rolling it, or transporting it in a vehicle or aircraft? Consider weight, size, handle design, and wheel options.

- Tool Organization: Do you need custom foam inserts, modular dividers, or pre-configured shelves? Efficient organization can save time and prevent tool loss or damage.

- Material Preferences: Each material (aluminum, composite, plastic, fabric) offers unique benefits and trade-offs. Weigh strength, weight, appearance, and maintenance needs.

- Security Features: Are lockable latches, tamper-proof hardware, or RFID tracking important for your application?

- Customization and Branding: Will custom colors, logos, or unique case dimensions help your organization stand out or improve workflow?

- Budget and Lifecycle Cost: Consider not only the upfront cost but also the expected lifespan and maintenance requirements of each case type.

Frequently Asked Questions (FAQs) About Tool Cases

- What is the best material for a tool case in a marine environment?

Waterproof composite or rotationally molded polyethylene cases are highly resistant to saltwater corrosion and moisture intrusion, making them ideal for marine, offshore, and coastal applications. - Are custom tool cases worth the investment?

For professionals with specialized or high-value tools, custom cases offer tailored protection, organization, and branding—often extending tool life and reducing replacement costs. - How do I clean and maintain my tool case?

Most plastic and metal tool cases can be wiped clean with a damp cloth and mild detergent. Inspect seals, latches, and hinges regularly to ensure continued durability and weather resistance. - Can tool cases be TSA-approved for air travel?

Many hard tool cases are designed to be airline-compliant and feature lockable latches. Always check current TSA guidelines and airline policies before traveling. - What organizational options are available inside tool cases?

Modern tool cases can include modular dividers, foam inserts, removable trays, pockets, and even electronic inventory tracking for maximum efficiency.

Enhancing Productivity and Tool Longevity With the Right Case

Investing in a high-quality tool case is not just about protection—it’s about maximizing productivity, reducing downtime, and ensuring your tools are always ready for use. The right tool case can mean the difference between a successful project and costly delays due to lost, damaged, or disorganized equipment.

Whether you’re upgrading your current tool storage or sourcing cases for an entire team, a thoughtful evaluation of materials, features, and customization options will deliver superior value and performance. For organizations with unique requirements, working with a custom carrying case manufacturer ensures a perfect fit for your tools and workflow.

Ready to Find the Perfect Tool Case?

Still have questions about choosing the right tool case for your business, industry, or project? Contact our team of carrying case specialists for personalized recommendations, quotes, and design assistance.

Conclusion: Invest in Tool Protection, Organization, and Efficiency

Tool cases are a vital investment for anyone who relies on tools or equipment in challenging environments. By understanding the different materials, manufacturing methods, and design features available, you can make informed choices that enhance organization, reduce tool loss, and extend the life of your valuable assets. Whether your priority is durability, waterproofing, portability, or custom organization, there’s a tool case solution tailored to your needs.

Take the next step in protecting your tools: Request a quote for your custom tool case today and discover how the right carrying solution can transform your workflow and safeguard your investment.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services