Hard cases are traditionally been fairly simple in design though custom and specialty cases are also widely used. Many are shaped like boxes and have packing material inside such as packing peanuts, heavy foam, special racks, shelving or a lining made of paper, foam, rubber, wood shavings, plastic or other materials. Read More…

One of the top carrying case suppliers, Princeton Case West provides quality carrying cases, custom cases, shipping cases, plastic cases, aluminum cases, tool cases, computer cases, instrument cases, transit cases and ATA cases. Princeton Case West offers custom foam inserts for varying applications. From design to delivery, Princeton Case West offers the complete package at affordable pricing.

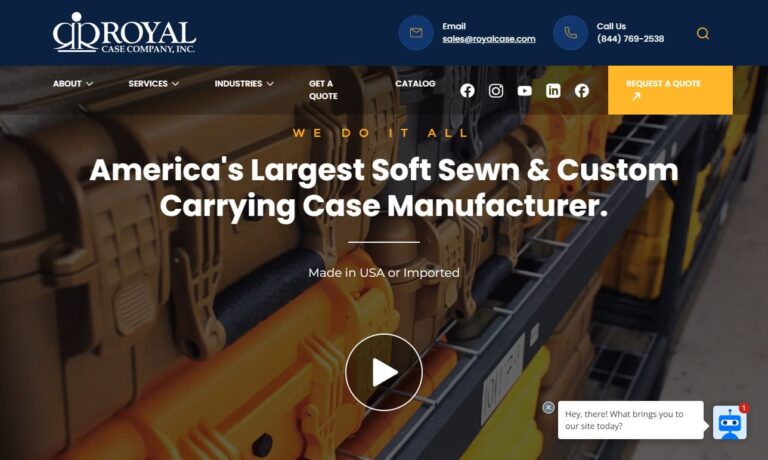

Royal Case Company, as premium carrying case suppliers, designs carrying cases based on industry specifications, including athletics, industrial and law enforcement. Through versatility and innovation, Royal Case Company offers a diverse carrying case product line including computer cases, plastic cases, aluminum cases, instrument cases, transit cases, custom cases, shipping cases and tool cases.

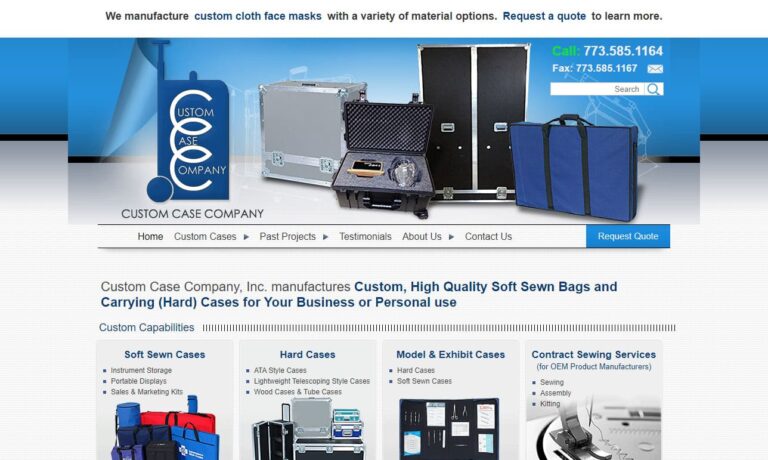

Our cases come in various configurations such as soft sewn cases, hard cases, model cases, exhibit cases, and more. We are experts in contract sewing and there is no project too complex for our experts. With manufacturing experience dating back to 1994 we are confident we can provide you with a top of the line custom carrying case.

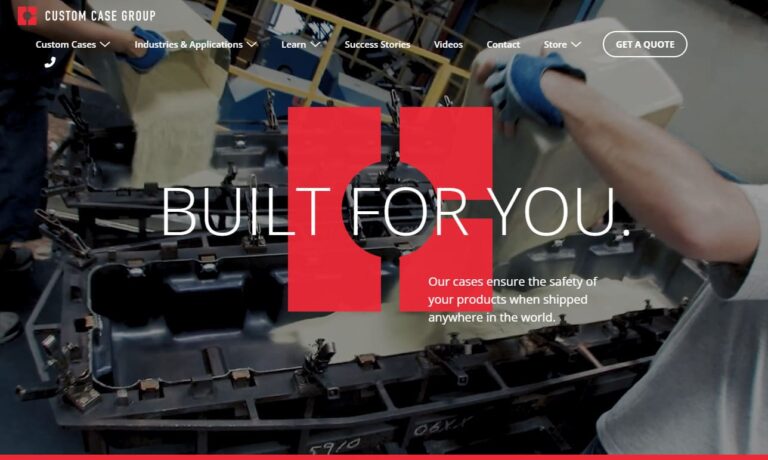

Custom Case Group (CCG) partners with Pelican, Anvil, Zarges, and Wilson to create custom cases for the aerospace, equipment, fire/rescue, hazmat, industrial, medical, military, OEM, oil and gas, shipping, and trade show industries. We also feature DroneHangar, a line of custom cases for drones and UAV/unmanned vehicles. Our engineers specialize in custom rackmount, carrying and shipping cases....

SBC Case Industries has provided carrying case solutions for over 22 years, and has proven to be elite carrying case manufacturers. SBC Case provides premium carrying cases to customers such as Home Depot and SaskTel. SBC Case is one of few carrying case companies that provide such a wide carrying case product range at a single source, including custom carrying cases, soft cases and hard cases.

S3 manufactures waterproof, crushproof cases and participates in the sale of HPRC cases of Italy. All S3 cases are made in the U.S. with stainless steel pins and high impact ABS. All cases carry a lifetime warranty and are virtually indestructible. Give us a call today!

More Hard Case Manufacturers

Others are shaped like briefcases and have pockets and organizers inside for that specific purpose. The automotive, athletics, business, outdoor, travel, medical, emergency, optical and music industries use hard cases to protect or organize items like camping equipment, first aid supplies, hearing aids, electronics, audio production equipment, musical instruments and firearms; hard cases are most also used for electronic instruments, computers, monitors, medical supplies, important documents, jewelry and many other items.

Hard cases can be customized and specifically designed to accommodate the contents. The packing material inside the cases may be cut in the pattern of the item or certain materials may be used instead of others. Straps, zippered pockets, rubber gaskets, shock mounts, enhanced and fortified steel or aluminum framing, buckles, heavy duty swivel casters, twist latches, spring loaded handles and other features are available to customize the case.

Many hard cases come with handles and wheels to allow for easier handling and transportation. The materials and fabrication methods used to manufacture hard cases have an impact on the case's performance, especially in terms of strength, shock absorption and fracture resistance. Blow molding is a procedure that creates a hollow part by applying pressurized air to a stream of hot plastic. Rotational molding is the process of rotating a mold while the plastic resin is being shaped into its final form.

Plastic cases may also be formed through injection molding where hot plastic is poured into a mold cavity and left until cool. FRP plastics have fibers that must be woven, knit, braided or stitched together before they are bonded to the matrix, a tough plastic surface. Metal cases are made from thick sheets of metal that have been fastened onto a metal frame. The corners are often reinforced with steel to counteract pressure applied during transportation.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services